From design to implementation, you can rely on us to take care of your IT Automation projects. Our team of industrial IT engineers understands your needs and will help you find the right solution.

IT Automation

Drawing on their solid skills ranging from automation to networks and from supervision to IT, they can ensure the overall management of all your automation projects.

Your IT Automation challenges

You want to ensure that your facilities run smoothly, simplify your teams’ operational tasks or improve data collection and management to optimise your processes. Our expertise in IT Automation, encompassing a broad array of services, can serve to meet these challenges.

Set up a monitoring system

Our experts will also configure your instruments and network elements (servers, VLANs, etc.), and then commission and set up the functions and controls.

Develop or improve your SCADA system

You are looking to interface your system or have specific requirements. When existing market solutions are limited, we can carry out specific IT developments (in .NET, Java, SQL languages, etc.).

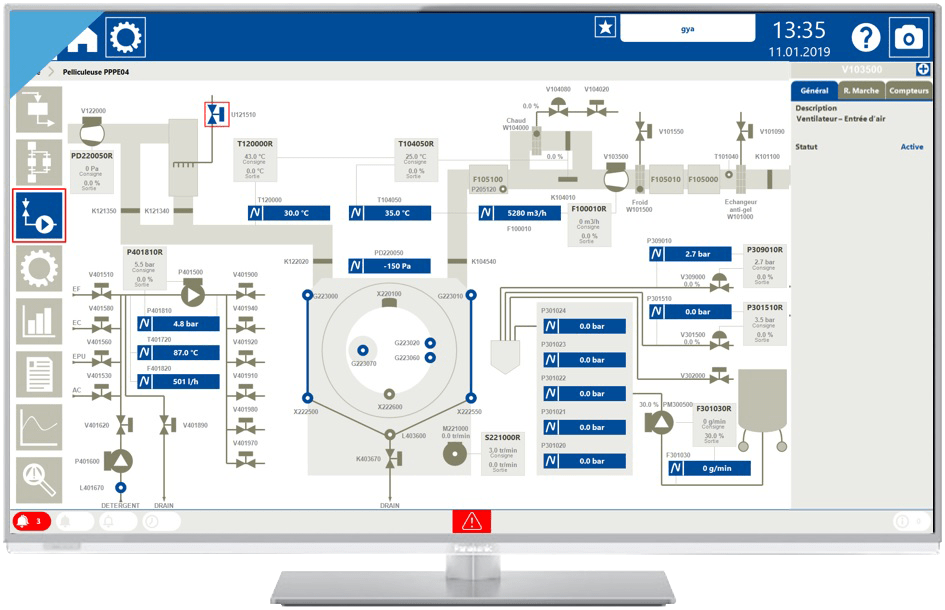

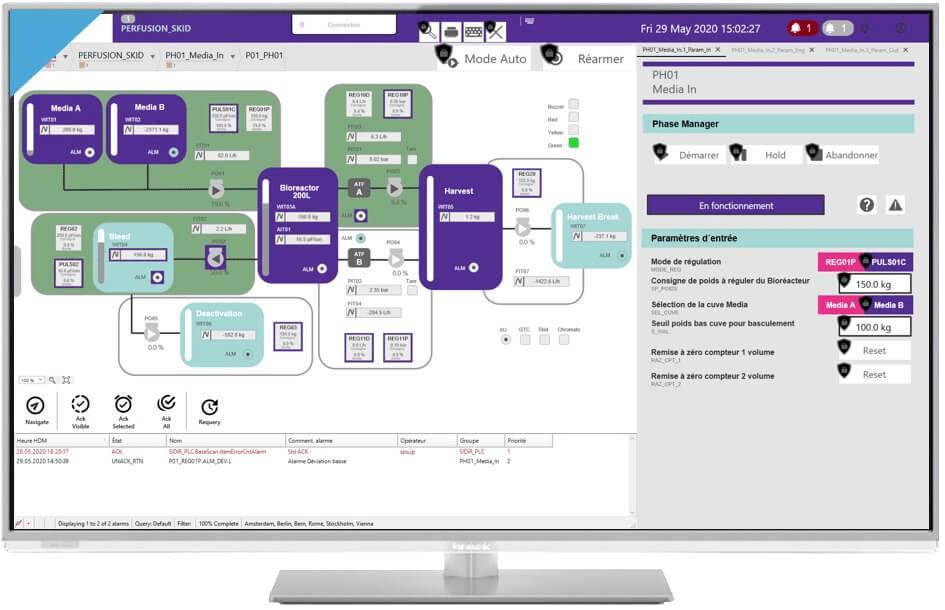

Harness an intuitive Human-Machine Interface (HMI)

In a UX approach (designed for user’ experience), we work as closely as possible with your teams to develop intuitive and easy-to-use HMIs. Our dashboards and functional views give you quick access to the information you need.

Collect and analyse your data

Data management helps improve processes and contributes to Enterprise Manufacturing Intelligence (MI). Automation thus supports analysis and decision-making so that you can continuously improve your facilities and processes. We are committed to making all the relevant information available to you.

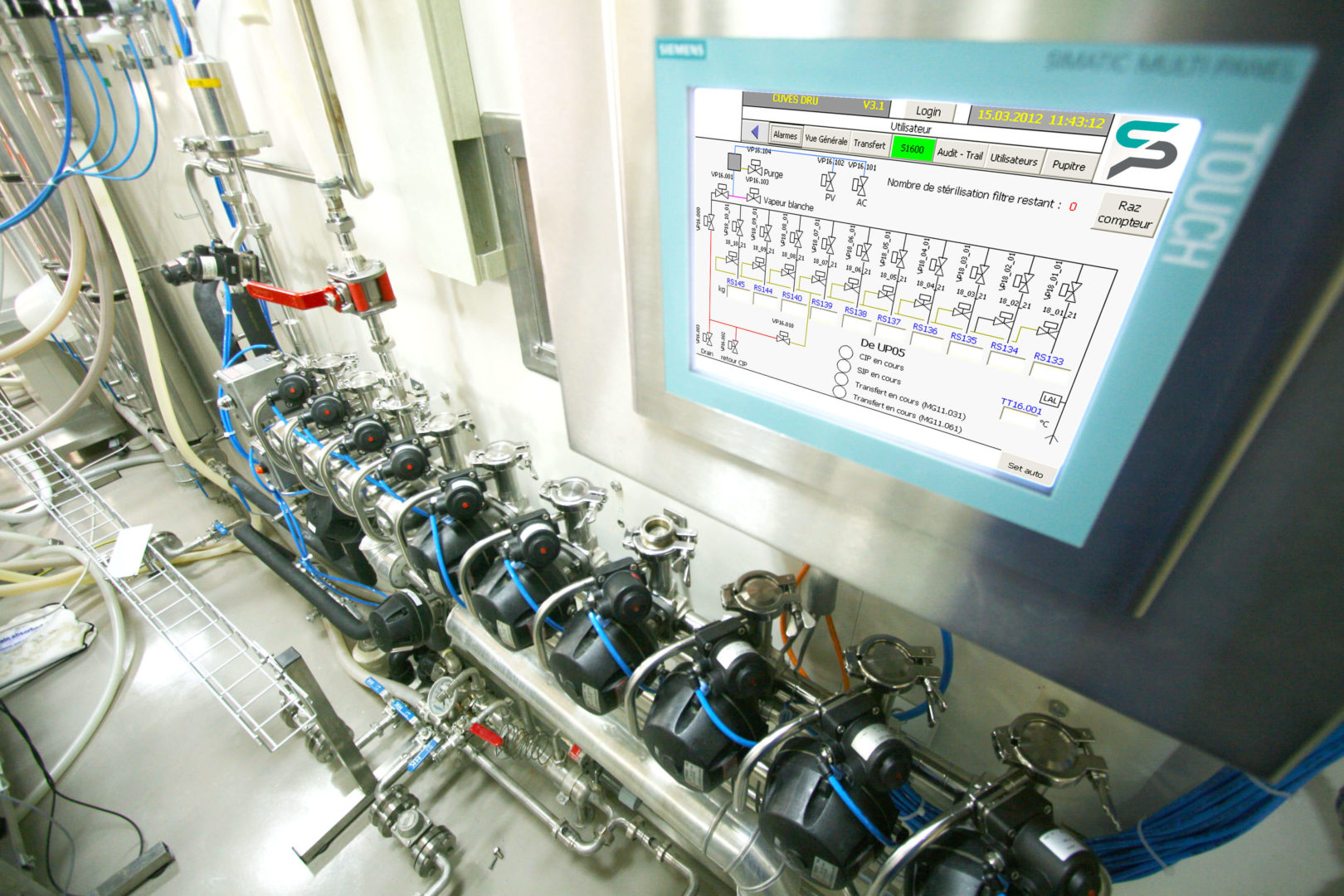

Secure qualifications/validation

Drawing from our experience in pharmaceuticals, biotech and fine chemicals, we implement GAMP5 requirements and create applications that comply with regulations (21cfrpart11, Data Integrity). Our global expertise enables us to accurately write FAT/SAT/IQ/OQ qualification test protocols.

Our sectors of intervention for industrial automation

Pharma, Biotech & Chemicals

This has become a capital skill in the field, where monitoring, supervision and oversight make it possible to optimise processes and comply with constantly changing regulations.

Companies in these sectors are now facing new challenges, including continuous manufacturing or multi-product facilities, where automation holds a vital role in device control.

We are experts in process engineering for fine chemicals, pharmaceuticals and biotech. We are perfectly aware of the stakes in this sector and have developed specific automation knowledge in this field.

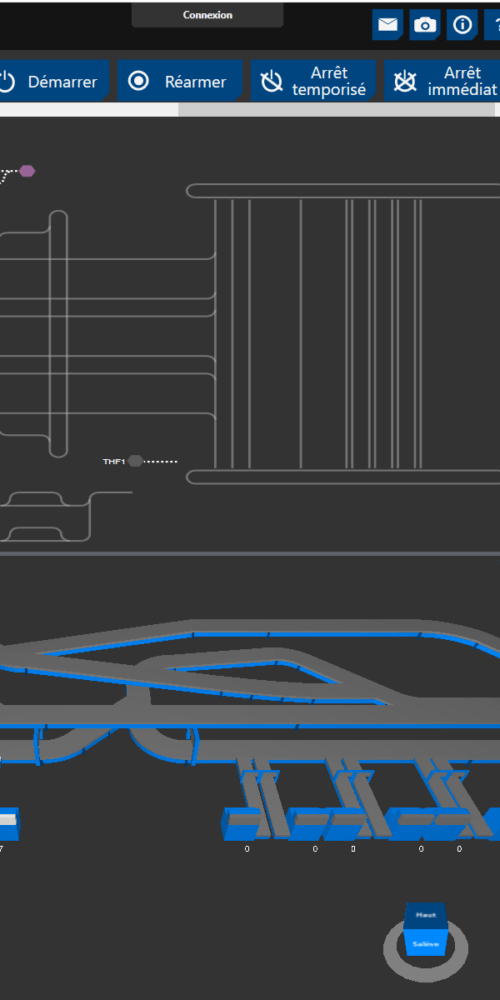

Airports & Data Centers

There are high stakes in these sectors regarding monitoring activities to ensure that the facilities operate smoothly.

Our dashboards can deliver customised indicators to simplify the daily work of your operational teams.

For example, we assist airports with their HMI interface for tracking baggage sorting.

Our distinction: User-centric HMIs

Our automation team specialises in the design and development of Human-Machine Interfaces that truly factor in end users.

Our collaborative HMI design method

Unlike traditional SCADA interfaces, we seek to develop interfaces designed to meet the needs of individual customers. Accordingly, our methodology comprises 4 steps.

Design universally accessible HMIs

Our approach must encompass all users: we thus work with a spirit of inclusiveness. Indeed, we pay particular attention to the use of colour palettes that are both consistent and accessible to people with colour blindness.

And because your teams use them over long hours, it is vital to think about their working comfort. We pay particular attention to the graphic style of our interfaces.

Soft colours render them comfortable on the eyes. Only important information (e.g. error messages) appear in bright colours.

Information organised from detailed to global

It is more than just a dashboard, we can also arrange different views according to your needs. For example, one dashboard with an overview (of your data), an intermediate view to control your facilities, and a detailed one for finer granularity…

You can therefore conduct in-depth studies on a trend or event, and also generate messages for recurring alarms on equipment. It is an indispensable tool for optimising your facilities.

We can also develop 3D views to simplify information reading, or additional views useful for data analysis: tools for configuration, diagnosis, history, logbook, messaging… enabling data analysis and optimising your equipment.

We can also adapt to your hardware by reducing HMIs for computers, tablets and smartphones. In addition to monitoring, IT Automation also enables analysis by viewing digital data.

Do you have an IT Automation project for us?

Let's talk about it!

Our business cases

Tank Revamping

Tank Revamping

LoRaWAN IoT platform

LoRaWAN IoT platform

LoRaWAN IoT platform

Clean Room

Clean Room

Clean Room

Geneva airport

Geneva airport