The cleanroom or whiteroom world is unique indeed. It is a world encompassing the invisible and subject to extreme control. Our multi-disciplinary teams of experts hold all the right cards to design perfectly controlled environments.

Cleanroom

Specialising in pharmaceuticals, fine chemicals or biotech, we adapt to your needs from the creation of your cleanrooms to the intervention on specific points. Much more than designing a box, we build a unique ecosystem.

The stakes involved in a cleanroom

You need a cleanroom where bacteriological growth is highly controlled and where temperature, pressure and humidity are regulated with extreme precision. You would like an environment where the risk of contamination tends towards zero. We can assist you in creating your own cleanrooms from design to qualification.

Mastering contamination risks

By your side, we are highly rigorous so as to minimise the risks of introduction, generation and accumulation of particles.

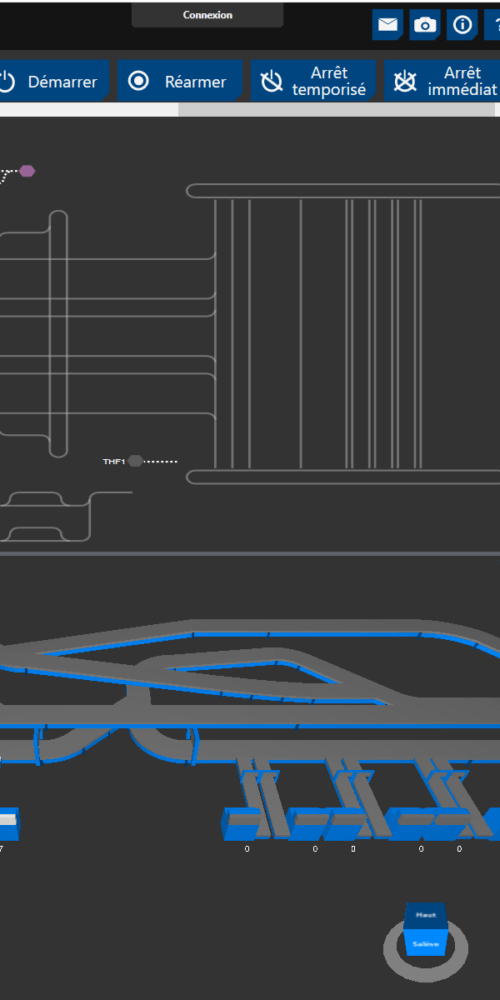

Drawing on our cross-disciplinary expertise, we study building systems (walls, partitions, suspended ceilings, floors, floor coverings, etc.), aeraulic systems, fluids, electricity, surveillance systems (monitoring, fire detection, gas detection) and all the equipment and materials installed in your cleanroom with the utmost care.

We move forward methodically to ensure that you can operate in the best possible conditions regardless of the contamination types.

During the design phase of the laboratory or production area, we study the flows and paths of your employees, especially for raw materials, products, packaging items or waste with a view to avoiding cross-contamination. Cleanability is also the source of our concerns so that your entire team has a working environment that perfectly suits the activity. We select materials and design your workspaces to preclude particle releases or blind spots that cannot be cleaned.

Ensuring the safety of everyone in a cleanroom

Like cleanliness, safety is a major issue. We are committed to ensuring a safe workspace for your employees by respecting the qualification of each area.

We propose designs that comply with the pertinent regulations in force to ensure the health and safety of your employees in general (labour laws -OLT 3 & 4, AEAI, etc.) or more specifically (ATEX, MSST, etc.).

We can also recommend dressing procedures designed to secure each stage of your activity: the cleanroom entrance is perfectly optimised for frequent round trips and operator movements.

We jointly develop our projects with your teams so we can clearly understand their needs and ensure their safety, thus facilitating the movements and work for your employees.

Unique cleanrooms

Communication is the guiding vector in our approach. We strive to provide a precise response, perfectly in line with your requirements and complying with standards, legislation and regulations. We take a collaborative, step-by-step approach to identifying and mitigating all the risks inherent in your business.

From feasibility to detail

First and foremost, we strive to understand your needs through numerous exchanges. The design phase enables us to lay the foundations for your future cleanroom. This is followed by budgeting and defining the facilities.

We can arrange visits to some of our clients to help you imagine your future environments. You can also meet our suppliers who develop specific solutions.

In a second step, the plans and initial visuals help you to project yourself. We then refine this into a detailed design before starting construction: matching your needs, optimised purchasing costs and operation, robustness and durability, safety and comfort.

At each of these stages, we jointly validate all the elements with you to move forward hand in hand.

From detail to operational

Given that contamination can come from both inside and outside, nothing should be left to chance when designing a cleanroom project. During the construction phase, we ensure that all the elements are carried out in accordance with the studies carried out thus far.

The qualification process for the built structures inherent to all cleanrooms – already launched at the beginning of the project – is now reaching its verification point: IQ (Installation Qualification), OQ (Operational Qualification)… We can either carry out or assist you in this process for the steps in terms of documentation and testing.

The understanding and integration of qualification protocols allows us to check each element of the facility and ensure the performance of your cleanroom. With facilities designed according to the standards applicable to your sector of activity, you will meet the requirements of legislation and international control agencies.

Limiting environmental impacts

With a view to respecting biodiversity and energy recovery, we implement procedures to minimise environmental impact.

Rationalisation of the opening of cold rooms, cryogenic reservoirs of genetic stocks, energy loops on fluids, programming the extinction of lighting… we guide you towards new practices.

Our sectors of expertise

Whether for commercial, trade or industrial premises, we take on any challenge to design your laboratory. Our expertise will also allow you to achieve the grades corresponding to your activities and your process (ISO and Class).

Biotech

The substances handled in biotechnology are so microscopic, rare and expensive that it is almost unthinkable that a single particle could affect their quality or yield.

This is why we pay particular attention to aeraulic solutions in order to avoid any risk of contamination. We have a control over cleanliness, humidity, sound, light and vibrations.

The stakes are so high with regard to health that zero risk is our leitmotiv.

Pharma & Injectable Cosmetics

Injectable products, products for local application or oral products… We satisfy the requirements of the pharmaceuticals sector with solutions adapted to the specifics of your production.

We therefore design pharmaceutical cleanrooms with a degree of quality and safety adapted to your needs while limiting the impact of the work on your business as much as possible.

We also use our cleanroom design knowledge to devise research and development laboratories that broadly meet the same constraints.

Do you have a cleanroom project for us?

Let's talk about it!