SP Groups has thrived alongside international players in a region historically known for its pharmaceutical industry. Initially experts in fine chemicals, we drew the best out of this territorial foothold to nourish our global vision and open up our horizons: from process engineering in fine chemicals, we have developed our skills in production processes for the pharmaceuticals and biotechnology sectors.

Process

Our innovative solutions and improvements in manufacturing processes can help you to achieve your goals in terms of cost, lead time and quality.

Chemical and process engineering

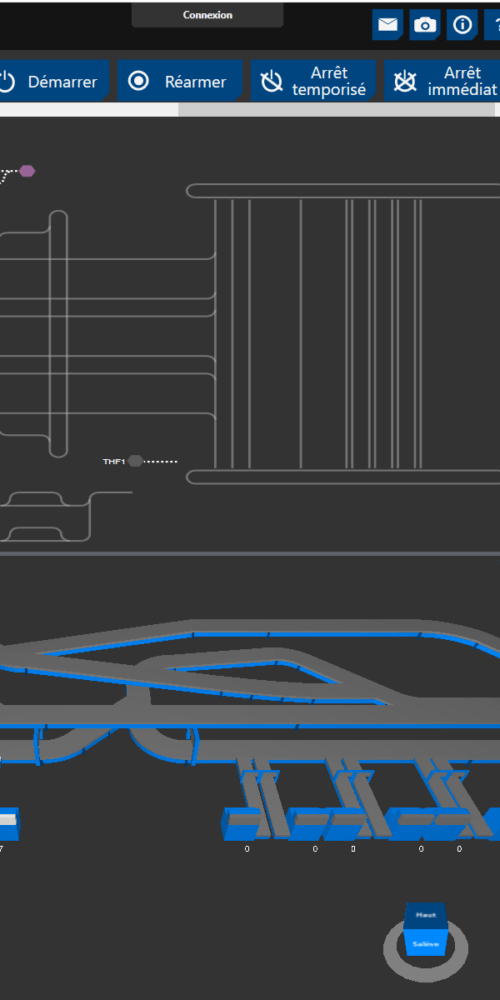

Our methodology and know-how in chemical engineering enables us to master to engineering process by extension. From fluid mechanics to flow management and work organisation, our involvement begins at the industrialisation stage of the manufacturing process.

While human and cargo flow management no longer holds any secrets for us, taking security aspects into account remains at the heart of our approach. As a result, we possess the ability to design, size and set up production units in various sectors of activity: chemicals, pharma, environment, etc.

The pharmaceuticals and fine chemicals sectors are both subject to stringent requirements in terms of process and operator protection (ATEX zone and exposure to harmful products). It is a matter of protecting human lives during both the production and marketing phases of the products. This is why every single one of our installations meet the requirements of classified environments and highly secure systems.

Designing the labs of tomorrow

Drawing on our experience and structure in the pharmaceuticals industry, we hold all the cards to design high-quality laboratories.

For our three favourite sectors, chemicals, biotech and pharmaceuticals, we develop:

- R&D laboratories

- Commercialised laboratories

- Small quantity production laboratories

Across these three large laboratory families, our engineering team has developed cutting-edge expertise in several fields:

- Clean fluids

- Laboratories classified according to biosafety levels BSL 1 and BSL 2

- Laboratories subject to a radioactive environment

- Cleanrooms

We are also able to supervise product cleanliness and protection in cleanrooms used for manufacturing APIs: depending on the product problem types, we can manage the different transfer phases in a contained approach to safeguard the operators. And if the product requires special protection, we control the atmosphere and the dust level in the area.

An industrial-scale challenge

Our process expertise in fine chemicals and pharmaceuticals can be adapted to the different types of reactions required, whether continuous, semi-continuous or batch, with startup, operation and shutdown phases.

The materials used in your installations will benefit from technical characteristics that are particularly adapted to your process and constraints (temperature, pressure or chemical resistance).

We work with black steel, stainless steel, hastelloy steel or coatings such as enamel steel and polymers.

Sector filters, high-pressure and low-pressure hydrogenators, multi-purpose and continuous reactors, Nutsche filters… Equipment that we have supervised with the greatest care for manufacturing pharmaceutical products, aromas, perfumes and electrolytes.

Climate engineering

Our multidisciplinary experience in climate, refrigeration and industrial process engineering enables us to design customised solutions adapted to your needs. Our expertise in the field of energy and air treatment enables us to design premises that are perfectly secure and totally controlled.

Heating, heat recuperator, air treatment system, integration of ATEX zones… Our mastery of all these elements ensures that you get a quality service in cleanroom HVAC.

Classification of clean zones (class or grade from A to D), ISO from 5 to 8

Biotechnological process: our cleanroom expertise

Over the years, we have developed a unique know-how in designing cleanrooms:

- UpStream Process (conservation and preparation of cell banks, cell culture, clarification, concentration)

- Media preparation

- Buffer preparation

- CiP (Clean in Place)

- DownStream Process (extraction biomolecules, purification, stabilisation)

- SiP (Sterilisation in Place)

- WiP (Washing in Place)

- Single use or stainless steel

Fluid process: utilities

Essential to the smooth running of your production, utilities are a process in their own right and treated as such. True ambassadors of our expertise, our engineers design your utility projects, both production and distribution in accordance with compliance requirements.

They command:

- Black utilities: industrial steam, compressed air, chilled water, heating water, drains, gas, etc.

- Clean utilities: clean or process gases, process compressed air, pure steam, purified water, WFI or EPPI water etc.

On the strength of our know-how and expertise, our entire approach to process engineering is designed to deliver reliable, controllable and sustainable solutions in terms of cost, quality, lead time and safety.

Are you looking to entrust us with a project in fine chemicals, pharmaceuticals, biotech, airports or data centres?

Let's talk about it!