At SP Groups, we are perfectly aware of the challenges facing the pharmaceutical sector, including its technical constraints and safety requirements. Are you looking for an ergonomic, clean and perfectly sterile environment conducive to a worry-free use of compounds to develop a drug? You can trust our expertise in laboratory design to guarantee the quality of products marketed according to Good Manufacturing Practices (GMP).

Pharma

Engineering solutions geared for pharma

Like fine chemicals and biotech, the pharmaceuticals sector leaves no room for error. Thanks to the expertise of our engineers and technicians in the laboratory and healthcare business, we hold all the cards to respond quickly and efficiently to your needs.

Reinforced security

When producing powdered medicines, injectable products or creams, the active ingredients must be handled with the utmost care. Extremely concentrated and sometimes highly dangerous, these active ingredients require a stable environment to prevent any risk of contamination.

We draw on our knowledge of the pharmaceuticals sector and the legislation regulated by the European and American health authorities to design facilities that meet your expectations.

A maximum level of non-contamination

Our niche when designing pharmaceutical laboratories? Ultra-cleanliness and flow control. In concrete terms, we take into account all the parameters that go into creating your facilities: Air treatment, finishing of partitions and walls, integration of furniture, design of personnel and equipment airlocks, HVAC ventilation, presence of special gases…

We do whatever it takes to protect your production from possible contamination and also meet the regulatory requirements for future qualification.

A “turnkey” building

Foundations, interior design, reception and maintenance… We manage the construction of your pharmaceutical laboratory from start to finish. Whether it is an analysis and control laboratory, a production workshop or a cleanroom, we adapt to your needs: handling area, sample reception area, GC area (gas chromatography), reagent storage area, weighing room, central pharmacy, decontamination and sterilisation area, test room or laundry…

We design each area with the utmost rigour to comply with safety and cleanliness standards. And the same goes for equipment integration! Scales, chromatographs, hydrogen generator, solvent cabinets, trolleys, sieves, technical area and maintenance access… We leave nothing to chance, and our engineers analyse everything to provide you with a tailor-made turnkey solution.

A multidisciplinary team

We have integrated profiles from various backgrounds over the years so we can offer a comprehensive range of products and services. Installation, programming, automation, IT… Our engineers conduct studies and supervise the different stages of your project in a collaborative approach. The purpose of this creative exuberance? Finding lasting solutions perfectly adapted to respond to your specific needs.

Know-how at the cutting edge of innovation

Driven by a desire to surpass ourselves and improve, we are constantly looking for new solutions to reconcile adaptability, efficiency and speed. Our engineers and technicians are trained in new technological practices and pool their expertise to ensure your satisfaction.

Our business cases

Tank Revamping

Tank Revamping

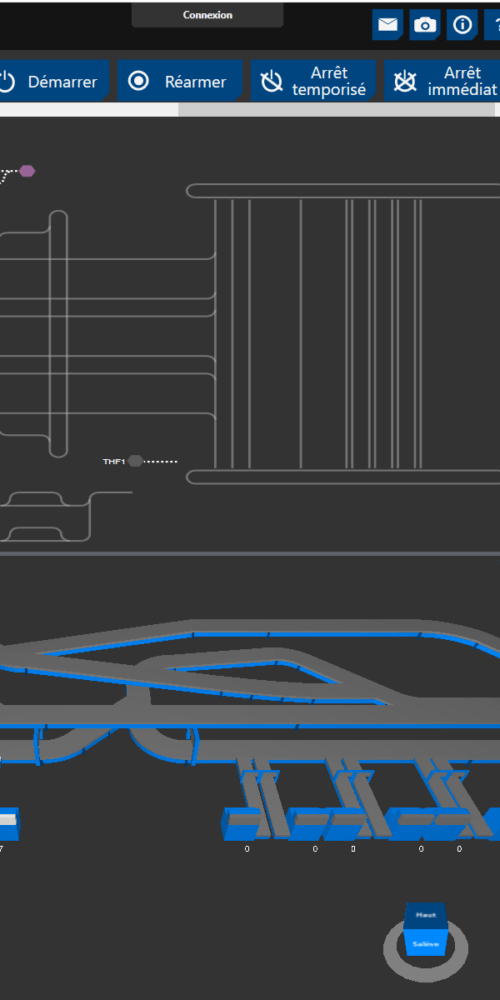

LoRaWAN IoT platform

LoRaWAN IoT platform

LoRaWAN IoT platform

Clean Room

Clean Room

Clean Room

Geneva airport

Geneva airport

Geneva airport

Discover our customers