In addition to revolutionising the health sector, biotechnologies are also changing industry, agri-food and environment sectors. Developments in biomedicines, cell therapies, vaccines, etc require secure facilities and supervised practices because they involve living organisms or their cellular components. We therefore design spaces and systems that incorporate a risk assessment approach. With SP Groups, engineering stands for rigour, quality and safety.

Biotech

Flexible solutions for biotech

Biotech has multiple applications in many fields, including biochemistry, genetics and molecular biology. These disciplines require precision, constant attention and consideration of risks appropriate to the production process. Bolstered by our experience in pharmaceuticals and fine chemicals, we adapted our processes to biotech. Our rule of three: zero risk, maximum efficiency and immediate reactivity! Research waits for no-one, so we opted to anticipate, innovate and shorten our lead times.

Contamination control

Microscopic substances and structures such as cells, molecules, strains and antibodies pose risks linked to living organisms. It is thus essential to design and build production units or Research and Development laboratories with an uncompromising approach. Our engineering consulting firm analyses, controls and supervises everything to provide you with an ultra-clean and perfectly sterile environment. Our goal?

- Working alongside you to develop a tailored, scalable and reliable process

- Protecting components and ensuring that the product is manufactured in the best possible conditions

- Safeguarding operators when handling potentially hazardous products or performing certain activities

- Safeguarding the environment against risks linked to handling potentially hazardous products: micro-organisms, GMOs, viruses, NCTA (Non-Conventional Transmissible Agents), etc.

Complementary expertise

SP Groups offers a tailor-made service of excellence to face the constantly evolving biotech sector and deliver a solution matching the challenges of safety and cleanliness. We interpret each constraint and integrate future users to bring a pragmatic and efficient response to all your needs. Our method for achieving the best system? Creating multidisciplinary teams and fostering a synergy of skills throughout the project. We can thus control flow management together with the technical nature of the equipment and other hardware essential to your activity!

Cutting-edge expertise in cleanrooms

Our cleanrooms are designed to strike a balance between ultra-cleanliness and safety: particulate concentration control, decontamination system, resistance to cleaning agents (H2O2), analysis of temperature, humidity, pressure… This also includes HVAC filtration and ventilation systems, air treatment and fluid management. Everything is analysed and integrated into the monitoring of your cleanroom via sensors in accordance with DQ/IQ/OQ/PQ qualifications. We are committed to sourcing the best materials, the best techniques and the best solutions to achieve GMP (Good Manufacturing Practices).

Technology serving biotech

Similar to fine chemicals and pharmaceuticals, the biotech sector leaves no room for error. We've harnessed the expertise of our engineers and technicians to build up a unique know-how in new technological processes.

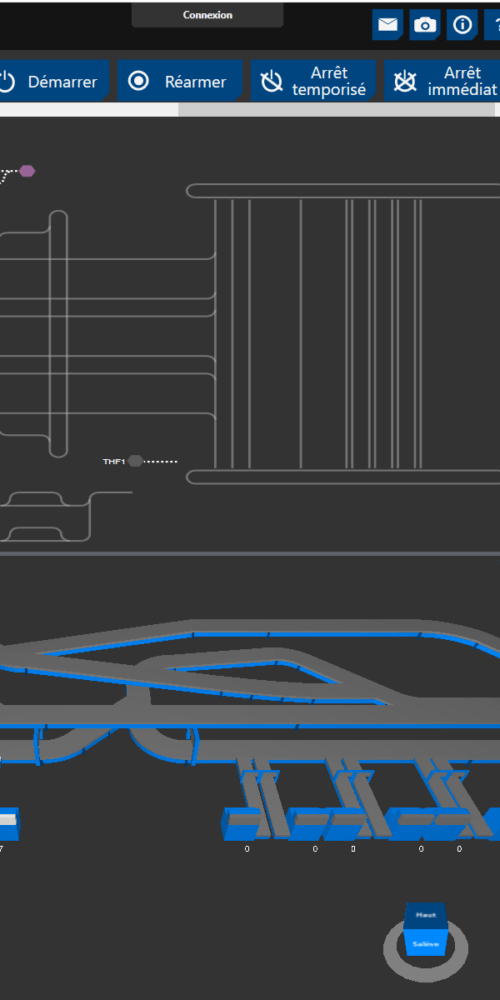

Automation in the biotech sector

Are you facing daunting quality, performance and regulatory challenges? Worried about delays, costs and regulatory compliance? With no room for human error and with elevated economic stakes abound, we offer technological solutions adapted to your needs. Drawing from our expertise in automation, we can design facilities for:

- Responding specifically to your operational needs

- Conducting and analysing in a user-friendly and relevant environment

- Observing regulations on GMP, 21 CFR part 11 and Data Integrity

- Expediting product commercialisation

- Ensuring the consistency of the process and quality of the product

- Reducing compliance costs

IoT and Data Integrity

IoT plays a key role in the technological revolution and opens up a new field of action for supporting biotechnological innovation. It encourages digital conversion and offers concrete applications: we notably integrate it into our monitoring solutions dedicated to biotech environments to streamline measurements (temperature, humidity, air flow, etc.).

We are also aware that this transition to the digital age must be accompanied by data integrity.

That's why we are working on data integrity and life cycle, from creation through storage.

Our business cases

Tank Revamping

Tank Revamping

LoRaWAN IoT platform

LoRaWAN IoT platform

LoRaWAN IoT platform

Clean Room

Clean Room

Clean Room

Geneva airport

Geneva airport

Geneva airport

Discover our customers