A historical sector at SP Groups, fine chemicals produces complex and very costly molecules through a highly specialised research and development process. The requirements for cleanliness, quality, traceability and qualification in this sector are extremely high. While we have been supporting players in this sector for over 20 years, we have developed unrivalled skills in the fields of process, ultra-cleanliness, automation, electricity and clean piping.

Fine chemicals

Innovative solutions in fine chemicals

Fine chemicals involves many industrial sectors. From pharmaceuticals to cosmetics, via electrochemicals and the fields of materials science, the molecules manufactured are always highly sophisticated. This is why we pay the utmost attention to contamination, cleanability and certification. How? By selecting the best materials, designing tailor-made systems and combining our engineering expertise with extreme rigour.

Adaptability to your needs

At SP Groups, we will certainly alter our habits and modify our methods to meet your expectations. There are no standard facilities in the fine chemicals industry, but rather unitary processes. Consequently, we build unique systems designed specifically for your business and adapted to your working methods.

Do you need to define the best synthesis route at the lowest cost? An ongoing process? A batch process? We implement all the necessary steps and choose the right tools for different types of reactions and extreme conditions. Temperature, pressure, atmosphere…

We analyse everything to forestall all risks of contamination, control the reaction, and assess risks to protect your production. Whether you are installing a new laboratory, a pilot unit, or want to modernise your existing unit, we provide you with a customised solution in accordance with Good Manufacturing Practices (GMP).

A co-design approach to prevent risks

Whether for new work, revamping, improvement or compliance, we choose to integrate future operators into our design process. Understanding the day-to-day life of operators is essential to prevent accident risks and issues linked to reliability and efficiency.

We therefore use workshops and a co-design approach to involve everyone concerned by the project. Equipment adapted to the type of activity or favouring co-activity, physical environments (lighting, noise, ventilation, air conditioning, heat exchange), work organisation, location of premises, escape routes, circulation and organisation of work surfaces…

All these points are addressed to ensure a high-performance solution adapted to your teams and your buildings.

Our technical expertise at your service

Fine chemicals is an extremely strategic field that requires highly technical yet occasionally toxic environments. Drawing on the skills of our engineers and technicians in process, automation, electricity, piping and control, we are capable of delivering turnkey solutions.

Exemplary compliance

In fine chemicals, handling certain components can pose elevated risks, especially when dealing with flammable gases or the emission of combustible dusts. To limit the risks, we carry out ATEX zone 0, 1, 2 zoning in powder, gas or both for laboratories, production units and even ISO classified cleanrooms: identification of hazards, definition of the extent of zones, duration of presence of ATEX environments, etc.

We conduct several checks during the various phases of the project as part of our compliance and qualification process. The first step entails Factory Acceptance Tests (FAT) at the factory of the process equipment manufacturer to check how the control system works and how the machine is manufactured. Site Acceptance Tests (SAT) are then carried out at the site where the installation takes place.

Finally, through a new series of tests, validations and IQ/OQ qualifications before commissioning, we systematically seek to optimise qualification by pooling certain tests in order to reuse them later for on-site qualification.

Our business cases

Tank Revamping

Tank Revamping

LoRaWAN IoT platform

LoRaWAN IoT platform

LoRaWAN IoT platform

Clean Room

Clean Room

Clean Room

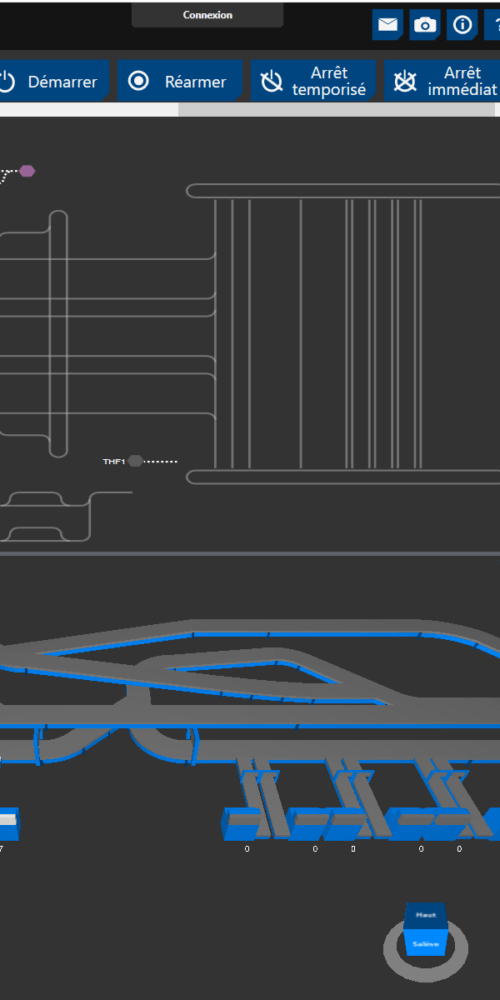

Geneva airport

Geneva airport

Geneva airport

Discover our customers